Seeing both wide and clear is a fundamental challenge. This is akin to taking a group photo with a smartphone: you want to fit everyone into the frame while also ensuring every face is clearly visible. In cutting-edge scientific research and industrial applications, this challenge is even more pronounced.

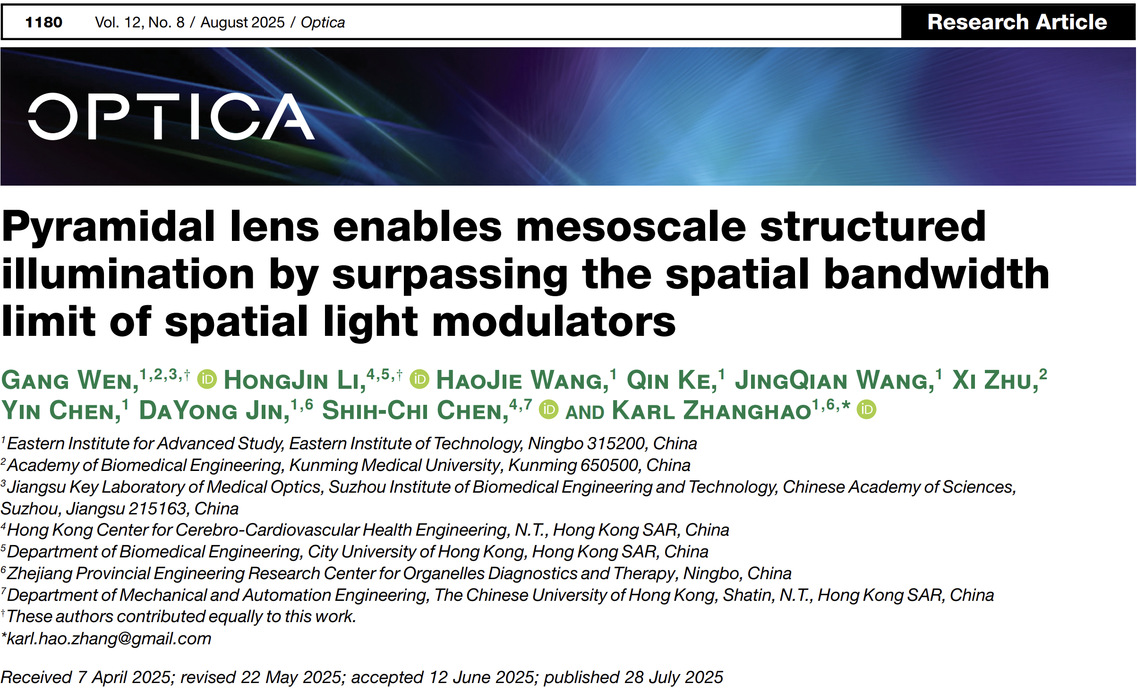

Recently, a team led by Assistant Professor Hao Zhang from our University's Faculty of Engineering, in collaboration with other researchers, published a groundbreaking study in the prestigious optics journal Optica, titled Pyramidal lens enables mesoscale structured illumination by surpassing the spatial bandwidth limit of spatial light modulators.

Inspired by photographic image-splitting lenses, the team innovatively designed a hexagonal pyramidal lens. This lens enables the generation and modulation of mesoscale structured illumination using only a small-sized projection chip, effectively boosting the equivalent pixel count of the chip by over two orders of magnitude. This breakthrough provides a novel solution for high-throughput super-resolution imaging and large-scale 3D metrology.

This pyramidal lens features a simple structure, ease of fabrication, and low cost, holding great promise for widespread application in fields such as optical imaging, machine vision, and industrial inspection.

The Inherent Trade-off: Large Field of View vs. High Resolution

Structured Illumination is a key technique in 3D precision metrology and super-resolution microscopy. Its principle involves projecting sinusoidal fringe patterns onto a sample's surface and using demodulation algorithms to achieve resolution beyond the diffraction limit or to reconstruct 3D topography.

However, a fundamental dilemma exists: simultaneously achieving high resolution and a large field of view requires projecting fine fringes over a large area. This places extremely high demands on the pixel count of the projection chip. Current mainstream projection chips typically have pixel counts in the megapixel range, which is often insufficient for frontier research and high-end industrial applications – it's difficult to see wide and see clear at the same time.

A Spark of Inspiration: From Kaleidoscopes to Image-Splitting Lenses

Inspiration sometimes lies hidden in the most ordinary toys and tools.

In a kaleidoscope, the reflection from three mirrors can transform a simple pattern into a dazzling, symmetrical display. Attaching an image-splitting lens to a camera lens can make city lights bloom into a dreamy starry sky.

These phenomena inspired the research team: Could exquisitely designed reflective or refractive optical elements be used to manipulate light paths, achieving a complex light field far beyond the inherent capability of the source itself with minimal effort?

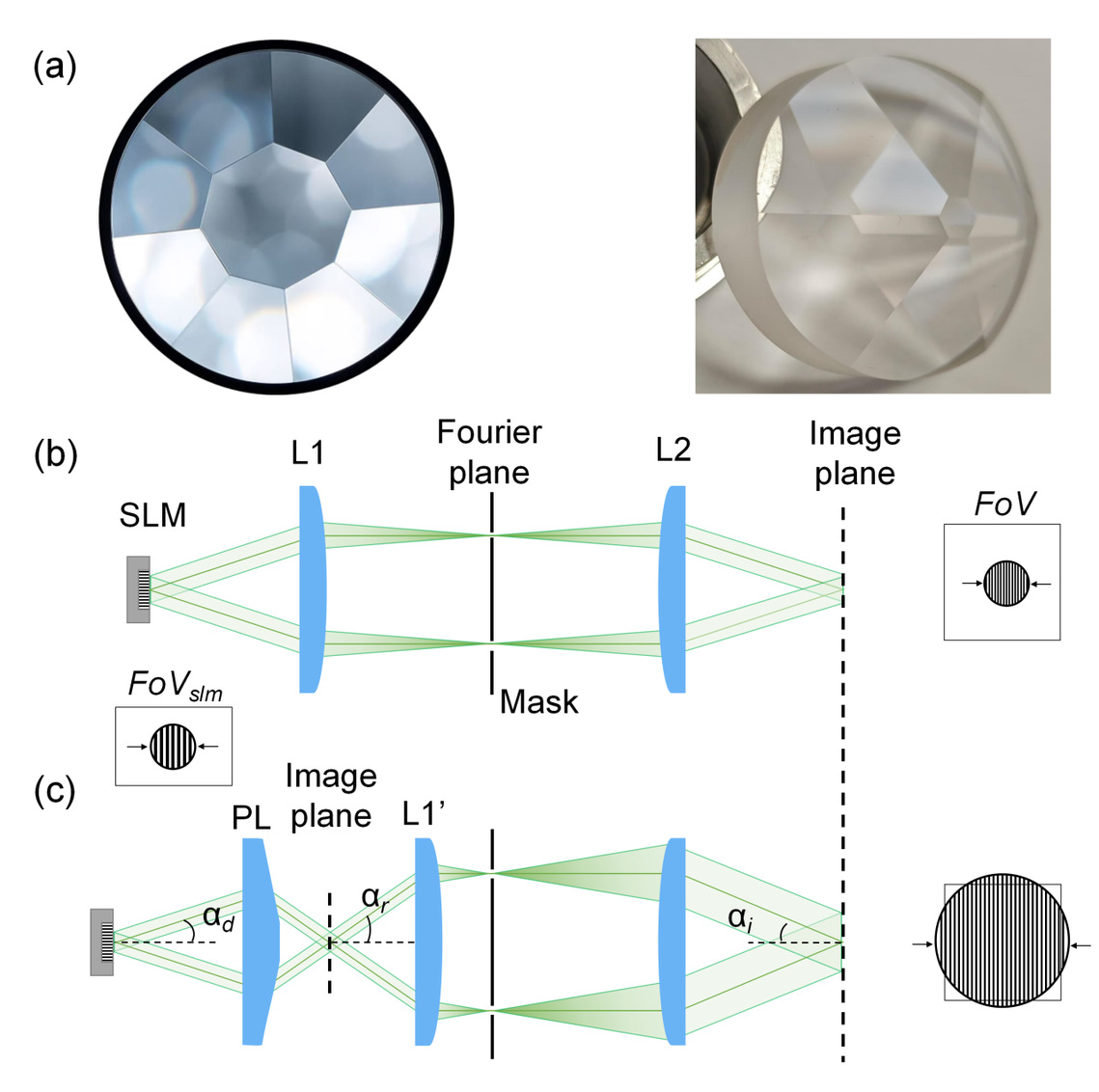

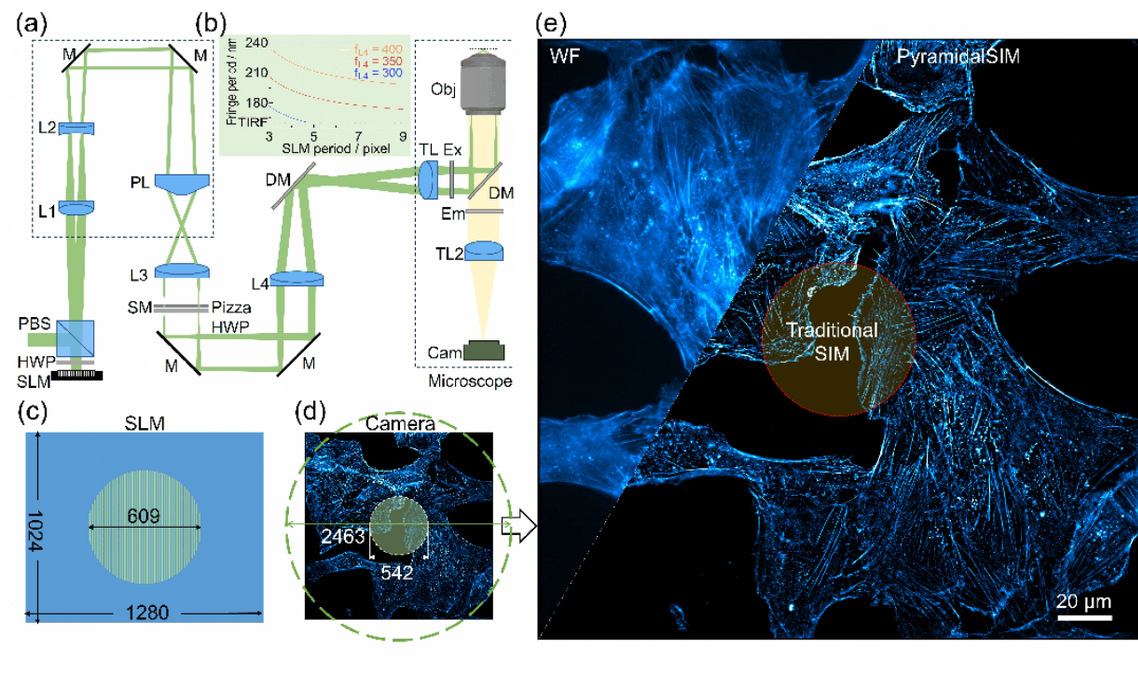

Figure 1 - Physical images of the photographic image-splitting lens and the custom-fabricated hexagonal pyramidal lens, along with a schematic demonstration of the principle by which the pyramidal lens generates fine fringes over a larger field of view through refraction of the ±1st-order diffracted beams.

Harnessing Complexity with Simplicity: The Magic of a Single Glass Element

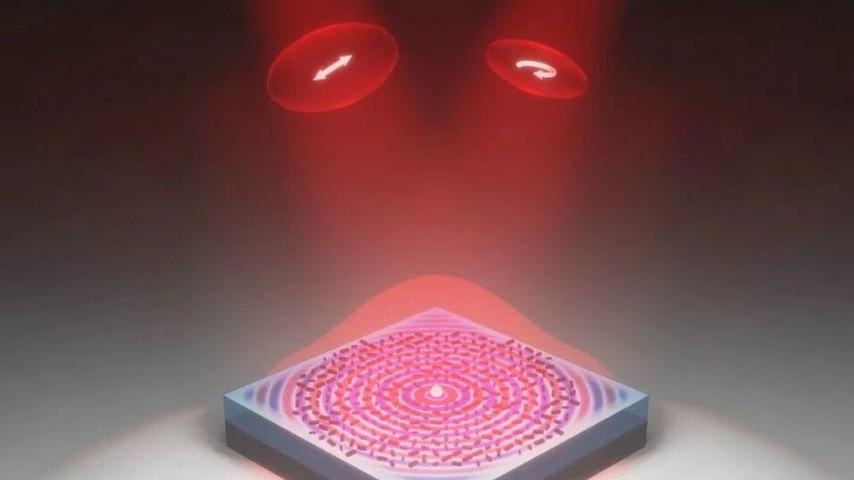

Inspired by kaleidoscopes, the researchers innovatively fabricated a glass element into a hexagonal pyramidal shape. Positioned after a micro-projection chip, this pyramidal lens enables precise manipulation of the ±1st-order diffracted beams emitted from the chip, deflecting them to significantly larger angles. The increased interference angle directly reduces the spatial period of the resulting interference fringe pattern—producing finer and denser fringes.

In this manner, a single, small pyramidal lens enables a projection chip originally capable of generating only a few hundred fringes to produce tens of thousands of fine fringes, effectively increasing its equivalent pixel count by over 100-fold and achieving mesoscale structured illumination.

Furthermore, the hexagonal pyramid design allows for precise control over the orientation and phase of the fringes via the projection chip. Experimental videos clearly demonstrate that simply inserting the pyramidal lens significantly expands the field of view of the structured illumination and drastically increases the fringe density.

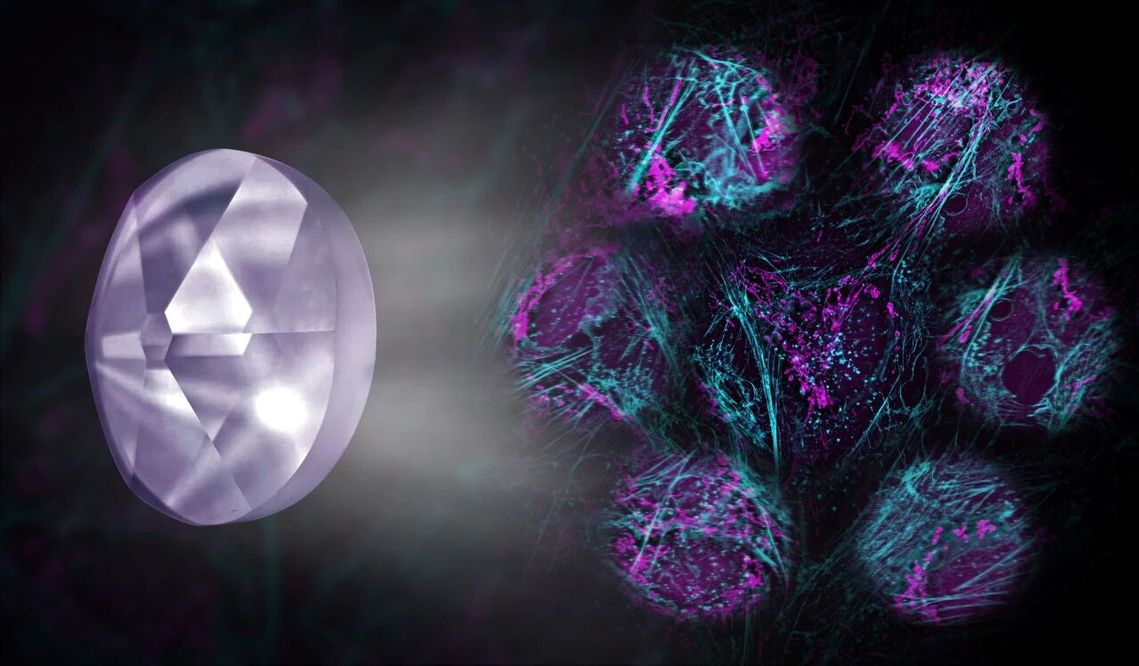

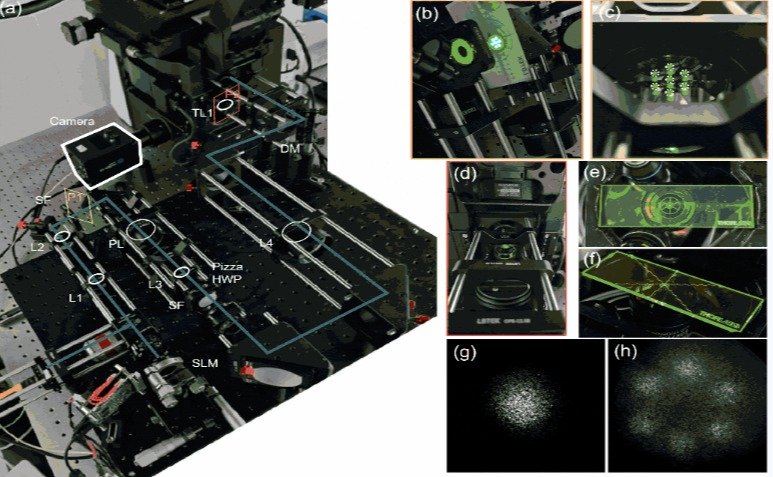

The research team integrated this pyramidal lens + projection chip scheme into a structured illumination super-resolution microscopy system, successfully building a novel super-resolution microscope-PyramidalSIM.

This system achieved 4K-pixel super-resolution imaging, a task traditionally requiring tens of thousands of projection pixels, using merely over 600 pixels from the projection chip. It simultaneously doubled the resolution, improving from 280 nm in wide-field microscopy to 138 nm. This technology leverages an extremely simple optical element to achieve efficient control of complex light fields, truly embodying the principle of harnessing complexity with simplicity. Without the need for expensive high-pixel-count projection chips, the simple addition of a low-cost glass pyramidal lens enables both large field of view and high clarity simultaneously.

Figure 2 - Super-resolution imaging based on the pyramidal lens-structured illumination and the corresponding results; along with the PyramidalSIM super-resolution microscope setup in the laboratory.

Eastern Institute of Technology, Ningbo is the first affiliation of this paper. Assistant Professor Hao Zhang is the corresponding author. Visiting Scholar Gang Wen (Kunming Medical University) and PhD student Hongjin Li (City University of Hong Kong) are the co-first authors. Other collaborators include Professor Shiqi Chen (The Chinese University of Hong Kong) and Chair Professor Dayong Jin (Eastern University of Technology. Ningbo).